HM De-S, Re-C, Re-Si at Tronox KZN Sands

HM De-S, Re-C, Re-Si at Tronox KZN Sands – Empangeni (RSA)

Treatment stands: 1

Injection lines: 2 (De-S and Re-C)

Ladle size: 60 t

HM Temperature: ≈ 1500 °C

De-Sulphurization: Injection of CaC2

Injection rates: CaC2: 30 ~ 40 kg/min

Injection lances: T-port

Transport gas: N2

Alloy addition systems: FeSi

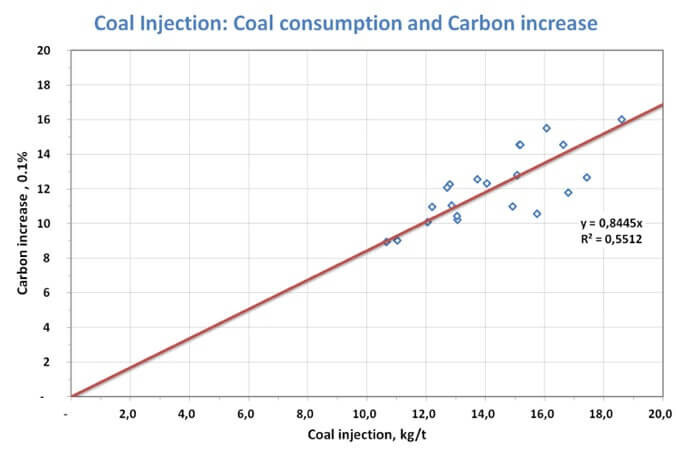

Re-Carburization: Injection of Graphite

(96 % fix Carbon)

Injection rates: Graphite: 60 ~ 80 kg/min

Transport gas: N2

Initial Carbon content: Ø 2.5 %

Final Carbon content: Ø 3.8 %

Injection time: Ø 16 min

Carbon consumption: Ø 15 kg/t

Carbon yield: ≈ 85 %